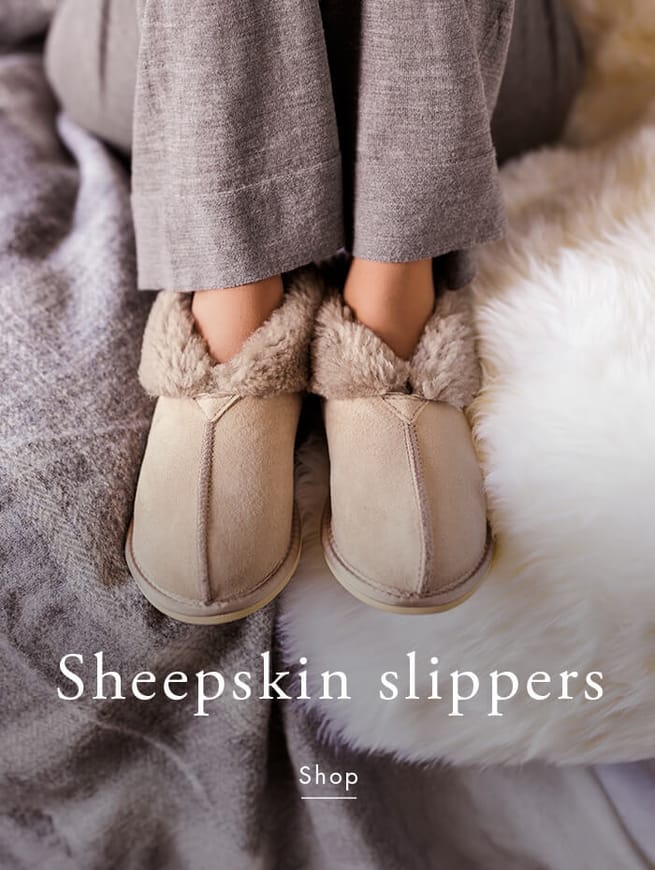

The Making of a Celtic & Co. Boot

Our Heritage

At Celtic & Co we’ve been making sheepskin boots by hand for nearly 27 years. Originally operating from a small lock up, we’ve grown to be one of the largest sheepskin specialists in Great Britain today, and we now manufacture our range of footwear within a purpose built factory on Cornwall’s beautiful north coast. Our attention to detail and expert craftsmanship has helped to give us a name synonymous with high quality.

Passionate About Quality

We begin the creation of each pair of boots by selecting a twin-faced footwear grade sheepskin, which is checked for imperfections before being cut using a metal template and a hydraulic press. Since sheepskin is a natural product, each skin can take the colour differently when it is dyed. To ensure every boot is perfectly colour matched to its partner, each of the panels used to make up a pair of boots are cut from the same skin. We believe in minimising our waste wherever possible, so smaller cuts of skin are used to create our Kids’ Celt Boots and the scraps are sold by the bag to our arts and crafts fans.

The Life Cycle of a Celtic & Co. Boot

Once the sheepskin has been cut the pieces travel to our sew room, ready to be assembled by our team of expert sewers – some of whom have worked with us for over 15 years. The main seams are double stitched on a cup seam sewing machine for maximum strength and longevity. The reinforced heelback is sewn on to improve the sturdiness of the ankle of the boot, ensuring it provides support to the wearer - unlike other brands of sheepskin boots, our heels should never collapse! Depending on which style of boot is being created we add any extras, such as a leather binding around the top to neaten the edge, or Toscana trims. The final step in the sew room is for the boots to have their insoles attached to the body of the boot and bound with nubuck.

The last stages of construction take place in our glue room, where the soles are attached using a waterproof and incredibly strong glue. Our soles arrive in sheets and are cut using metal templates and a hydraulic press – this means we can cut multiple sizes from the same sheet, which is especially useful when it comes to rushing out single Christmas orders! The top of the soles are sanded to improve their grip before the adhesive is brushed on. The process in which our gluers work means that the glue is given time to cure and become tacky before the sole is attached. Once the soles are perfectly lined up the boots are pressed to ensure the soles are firmly secured and the edges of the soles are given another quick sand to remove any hard edges.

Last but by no means least, the boots make it to our checking department. Although the work is quality controlled at every stage in the manufacturing process, they are given one final inspection to make sure they meet our stringent quality standards. Before being carefully packaged ready for shipping, they are given their care instructions – so you can be sure you continue to treat your boots with the love they deserve!